Trade Assurance ASME Standard Stainless Steel Pressure Vessel Storage Tank

Basic Info

| Model NO. | 1000L |

| After-sales Service | Online Support |

| Warranty | 12 Months |

| Function | Storage Pressure Vessel, Separation Pressure Vessel, Reaction Pressure Vessel |

| Application | Mixture |

| Material | Carbon Steel |

| Pressure | 1.6MPa≤p<10.0MPa |

| Storage Medium | Moncombustible/Nontoxic |

| Pressure Level | Medium Pressure (1.6MPa≤p<10.0MPa) |

| Condition | New |

| Heating Type | Jacket/Coil Heating |

| Agitator Type | Customized |

| Colour | Customized |

| Operation Pressure | 5MPa |

| Mdmt | -20ºC |

| Liner Material | PTFE |

| Transport Package | Standard Export Package |

| Specification | customized |

| Trademark | Stordworks |

| Origin | China |

| Production Capacity | 1000L |

Product Description

Jacket Design Hemp Ethanol Extraction Spinner with ASME and U stampProduct Description

1. Types: storage tank, air storage tank, liquid storage tank, vertical storage tank, horizontal storage tank, spherical tank, carbon steel storage tank,low-alloy steel storage tank, stainless steel storage tank and so on.

2. Materials: carbon steel, low-alloy steel, stainless steel and non-ferrous metals: titanium, nickel, copper, aluminum, molybdenum, zinc, cobalt etc and their alloy materials.

3. Pressure: low-pressure, medium-pressure and high-pressure.

4. Temperature: low-temperature heat exchanger, medium-temperature heat excahnger but also high-temperature heat exchanger.

5. Medium: not only non-flammable,non-toxic and non-corrosive medium but also flammable,toxic,corrosive medium and highly flammable,highly toxic, highly corrosive medium.

6. Processing capacity:maximum diameter:6m; maximum length:60m;maximum weight:600tons

7. Applicable Industries: petrochemical, coal chemical, precision chemical, nuclear power, metallurgical, pharmaceutical, machinery, food, pesticide, rubber, aerospace, marine, dye, new power equipment and so on.

8. Our advantages: reliable quality,codial service and great price.

Jacket Design Hemp Ethanol Extraction Spinner with ASME and U stamp technical parameter

| Model | 300L | 400L | 500L | 600L | 1000L | 2000L | 3000L | 5000L |

| Vessel Op. Temp. (MPa) | 0.1-10Mpa | |||||||

| Jacket Op. Temp. (MPa) | 0.1-10Mpa | |||||||

| Motor Power (Kw) | 0.55 | 0.55 | 0.75 | 0.75 | 1.1 | 1.5 | 1.5 | 2.5 |

| Stirring Speed (r/m) | 36~53 | |||||||

| Diameter (mm) | 900 | 1000 | 1150 | 1150 | 1400 | 1500 | 1700 | 2000 |

| Height (mm) | 1800 | 1900 | 2200 | 2300 | 2600 | 2900 | 3200 | 3700 |

| Heat Exchanging Area (m2) | 2 | 2.4 | 2.7 | 3.1 | 4.5 | 7.5 | 8.6 | 10.4 |

This equipment is used in the process of hydrolysis, neutralization, crystallization,distillation and evaporation in pharmaceutical, chemical, food, light and otherindustries. It can use SS304, SS316L, Titanium, Hastelloy, PTFE lined and other materials to manufacture. Several mixing types are available, such as anchor, frame and oar, etc.

Cycloidal pinwheel reducer, variable-speed reducer and others could be applied in the rotating mechanism. The sealing device can use machines; Sleeve, semi-tube and coil pipe structure can be used in heating and cooling. There are several heating modes, such as steam, electric heating, heat conduction oil, etc. In order to meet different requirements of acid-and alkali-proof, high temperature resistance, wear resistance, corrosion resistance and others under different working environments, reaction kettles can be designed and manufactured based on clients' requests.

Packaging & Shipping

We can deliver the goods to you by sea,by air,by express or by land transportation.We will try my best to make you get the goods faster and safe.Package can be designed according to require, please contact in advance.

Company Profile

JIANGSU STORD WORKS LTD. located in Fangqiao National Machinery Industrial Park, which at the Taihu Lake, Yixing City, Jiangsu, China. Our company is a professional equipment manufacturing base specializing in comprehensive utilization and recovery of solid and liquid waste. The main products of our company are sludge drying/incineration and the accessory equipment, liquid waste evaporation & concentration equipment, complete equipment for animal rendering plants, pressure vessels and other non-standard equipment. StordWorks adheres to the international first-class quality standards and strictly controls the product details. Our products are sold well in European Union, USA, Australia, etc. and have been unanimously praised by customers at home and abroad and highly recognized by the market.

Major products of the company are stated as follows: 1. Drying series: disc dryer, blade dryer, tube bundle dryer, coil dryer, sludge dryer, etc. 2. Squeezing and pressing series: twin screw press, single screw press, animal oil press. 3. Cooking & hydrolyzing series: continuous cooker, batch cooker, feather continuous hydrolyzer. 4. Evaporation and concentration series: multi-effffect evaporator, MVR evaporator, scraper evaporator, molecular distillation equipment, etc. 5. Crushing & grinding series: single-axis crusher, double-axis crusher, four-axis crusher; powder hammer mill; bone crusher;meat crusher. 6. Conveying series: screw conveyor, screw cooling conveyor, mesh belt conveyor, scraper conveyor, belt conveyor, etc. 7. Non-standard and pressure vessels: heat exchanger, reactor, tower, storage tank, etc. Equipment material can be carbon steel, stainless steel, dual phase steel, Titanium, nickel - based alloy, hastelloy, copper, etc. StordWorks has the specialized workshop for drying machine production and advanced tooling equipment. We also have various international pressure vessels certification and abundant experiences in equipment manufacturing, such as National standard pressure vessel certification, American ASME certification, Norske Veritas DNV certification, and EU PED certification. Jiangsu StordWorks obedience to the business philosophy of "Focusing on Professionalism & Quality First", and the service concept of "Customer-orientation and Exceeding Customer Satisfaction". By means of our excellent quality and perfect service, Jiangsu Stord Works Ltd. sincerely looks forward to cooperating with you!

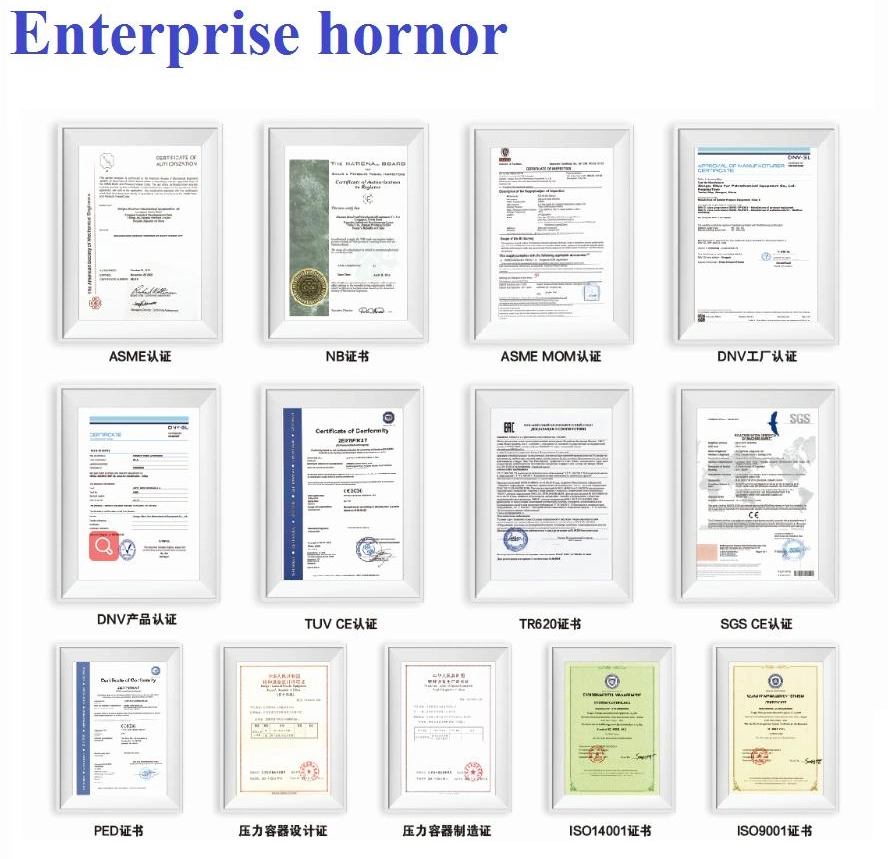

Certifications

Our factory has acquired the certificate of Quality management system ISO9001,ISO14001, Manufacturing license of pressure vessels, the manufacture certificate of boiler pressure vessel issued by ASME U stamp and NB certificate, PED certificate ,DNV certificate and so on.

FAQ

1 ) How can we visit your factory? If you come from abroad, air to shanghai airport, then we can pick you up at airport. If you come from domestic city, air or train directly to Wuxi station. We will pick you up at railway station.2) How do you ensure the quality of your products? Our Company has more than 10years experience in this filed , strict operation policy is performed, advanced processing machines guarangtee the precision of all components, workers with operation license, parts get multiprocessing, transmission& electrical parts are of international famous brand. Series of test and inspection are done in the whole producing state.3) How long is the service time? It could use several year without external force factors. We have 1 year warranty.4) What is the payment terms? We accept T/T and L/C. 5) Can you make as per custom drawing? Yes, we can do that.

![[MID Year Hot Sale] Chemical Storage Vertical Water Softener FRP Tank /FRP Pressure Vessel/ Water Filter Tank/ Water Treatment 0844/1054/1252/1354/1465](/uploads/s/c306e182839a4f0fa60579ab4d45df19.webp)